Tool control

Magema B.V. has all the resources to offer a total solution in the field of tool control.

Tool control is the collective name for systems that trace, store and retrieve tools and fittings in a verifiable manner. Its principle originated in the medical industry, but its use has been obligatory for quite some time in the aviation industry as well. The traceability, in particular, is crucial in this industry, as companies wish to be certain that all used tools and parts are removed from the aircraft and/or engine after a repair or modification.

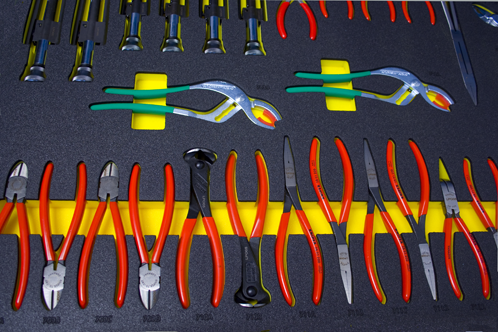

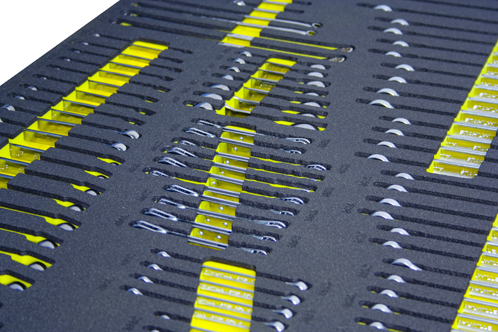

Magema B.V. has the required machinery and software to create a tool control project completely in-house. As a result, you can be sure of a set and customised lay-out that is entirely according to you needs and wishes. All tools are milled out three-dimensionally in a foam layer. The background has a bright, contrasting colour, so that a missing tool is detected immediately. To identify the missing item, the contours can be labelled with identification numbers.

Magema B.V. has all the resources to offer a total solution in the field of tool control.

Tool control is the collective name for systems that trace, store and retrieve tools and fittings in a verifiable manner. Its principle originated in the medical industry, but its use has been obligatory for quite some time in the aviation industry as well. The traceability, in particular, is crucial in this industry, as companies wish to be certain that all used tools and parts are removed from the aircraft and/or engine after a repair or modification.

Due to its 3D-milling technique, the Magema B.V. Tool control program has a unique quality.

Each item is individually drawn and milled out to its own depth. The result is a very clear inlay, in which all the articles are close to the surface.

This way of milling, together with the clear contrast layer, make a visual inspection on completeness very easy. In addition, this conscientious way of producing a perfect fit for each article, makes misplacing items a thing of the past.

Since it produces tool control sets in-house, Magema B.V. is always willing and able to think along with the customer in case of special projects.

Carrying cases for expensive equipment, in-foaming special tools, or "non-tool control" tool sets are just some examples of projects where the requirements of the customer are translated into a final product.

The production area of Magema B.V. consists of three 3D-production machines. In addition to these three production machines, Magema B.V. has a smaller "prototype" machine, which can be used to produce specials and small-scale productions.

Since it produces tool control sets in-house, Magema B.V. is fully flexible when it comes to backorders, adjustments or urgent deliveries.